Design

Considerations in shade structure design

Click to view section

The Brief

Collaboration

Shade structure design involves all parties; client, builder, architect, engineer and regulators. Collaboration is key to a successful project.

The client needs to be confident in their installer’s knowledge and ability. Abacus Shade Structures is supported by experience and reputation. With over 35 years building shade structures we know shade structures.

Parameters

Parameters set the boundaries in which to design. Parameters may include maximising shade, avoiding western sun, working within existing landscape & buildings, ideal times for use, rules, playground equipment heights, sub strata services or soil types and site access. Good design considers parameters.

Purpose

What does the structure needs to achieve? Is it visibility, function, aesthetics, rain protection, sun protection, privacy, refurbishment or a combination of these. Each structure is unique.

Budget

Finding the right price balance is a challenge. Projects vary in complexity, quality of materials used, finishes and purpose. These factors affect pricing.

When comparing shade structures to other outdoor building products available, shade structures are a competitive alternative with low initial cost, low maintenance costs and zero operating costs.

Basic Shapes and Form

Curves

Sails have curves. Curved sides also called catenary curves occur between connection points to tension and spread load imposed on the fabric when there is no other frame. Tension applied by a perimeter cable imposes forces which want to straighten the curve. This lead leads to a tightening of the sail and the main characteristic feature. Curves range from 5-10% of the length of each sail side. Curves must be considered in design.

Umbrellas

Umbrellas, Inverted Conics, Claws and Hypar Umbrellas fit into this category which is characterised by one or more peaks supported by a central or side mast. A central ring may connect the fabric to the central mast to facilitate erection and stressing of the fabric. A Hypar Umbrella has one mast and alternating high low corners like a sail.

Sails

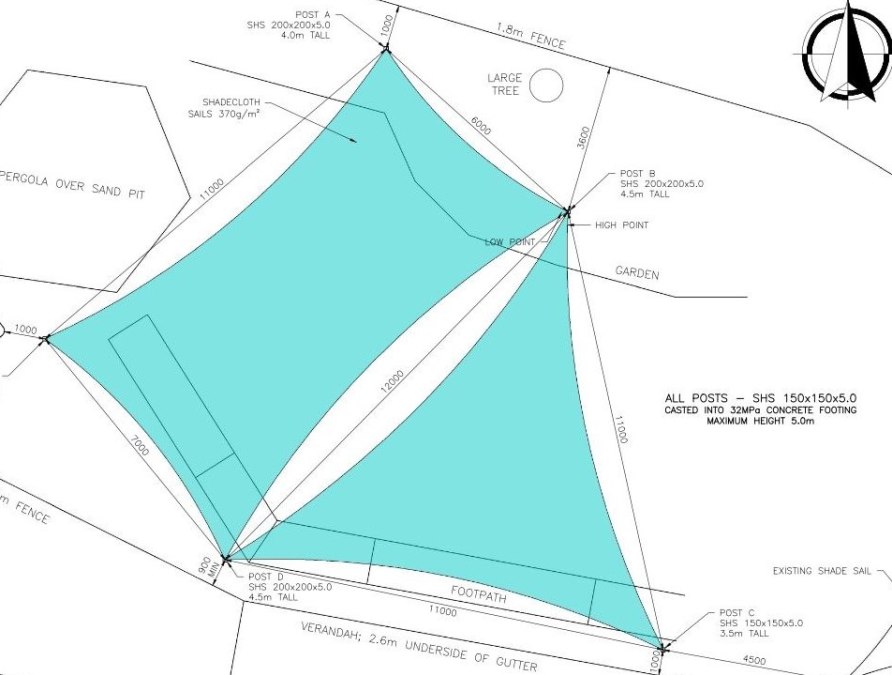

A simple saddle system or Hypar Sail is a three, four or more pointed structure formed when the fabric is tensioned firmly between a set of alternating high and low points. Much of the appeal of hypar sails is in the three dimensional (3D) twist and saddle.

Another sail style are the Repeat Pattern Sails. Fabric is supported by parallel posts with the fabric alternating between high and low points on each posts as multiple sails.

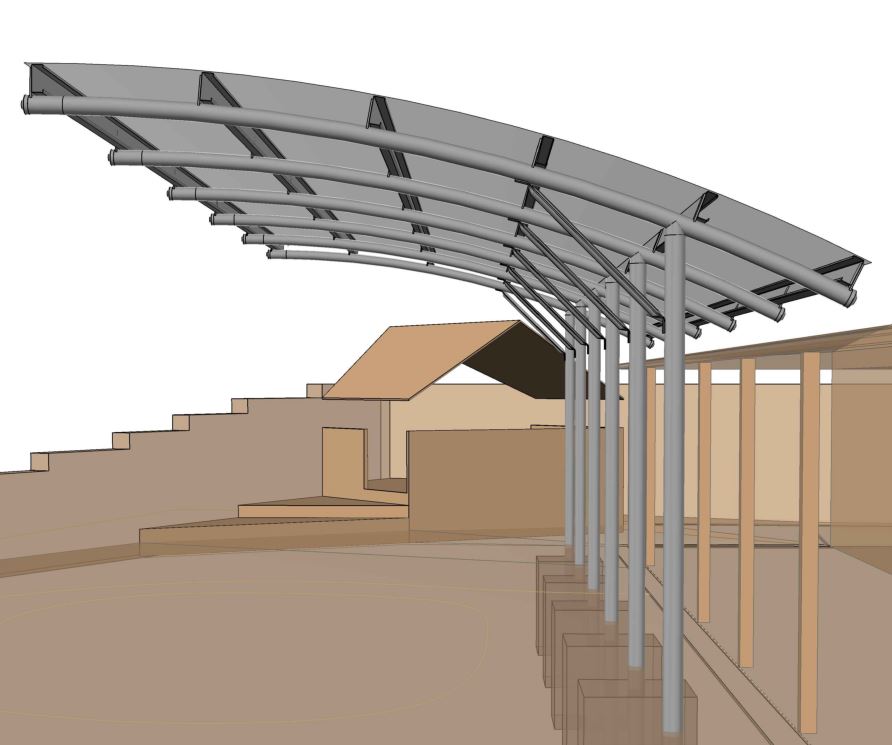

Arch Supported Systems

Cantilevered, Gull Wings and Barrel Vault Structures. These designs avoid interior post supports by introducing curved compression members as the main supporting element for lateral stability. Cross arches or diagonal bracing may be used. These systems are capable of spanning large distances.

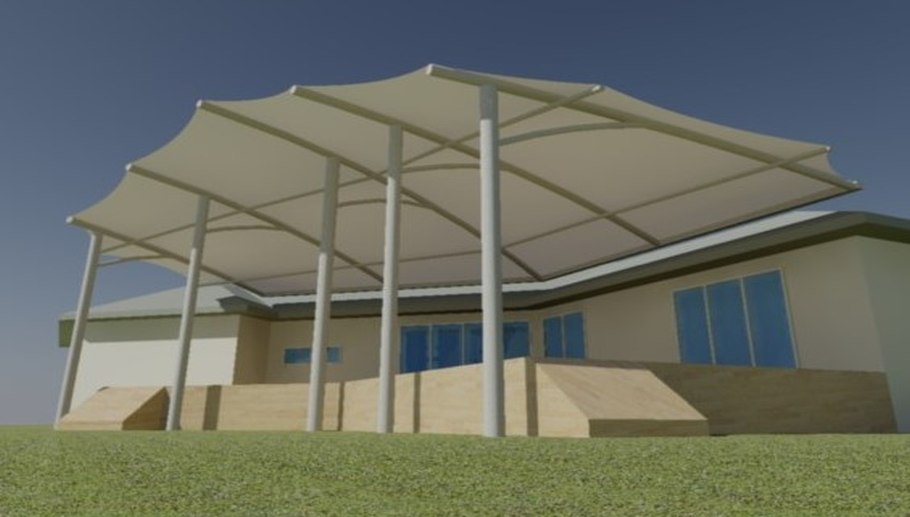

Hip Roof Structures

Span Shades belong to this category which is characterised by a strong overhead framework supported by straight steel members and a membrane roof. Hip roof structures are modular and can be linked together.

Components

Membrane Fabric

The membrane fabric forms the roof of the structure. Knitted shadecloth and PVC are types of membrane fabrics. Fabric may be sewn, glued, electronically welded or heat-sealed to form a permanent strong seam and edge. Fabric properties include strength, thickness, elasticity, UV resistanc, coating thickness and anti-mould & anti-wicking treatments.

Posts and Framework

The steel support frame is the heaviest component of the structure. The structure design and engineering specifications sets sizes of steel posts, sizes of overhead beams, steel diameter & wall thickness and method of fixing at ground level. Steel frames may be curved or straight, round (CHS) or right angled (RHS). All structures are unique.

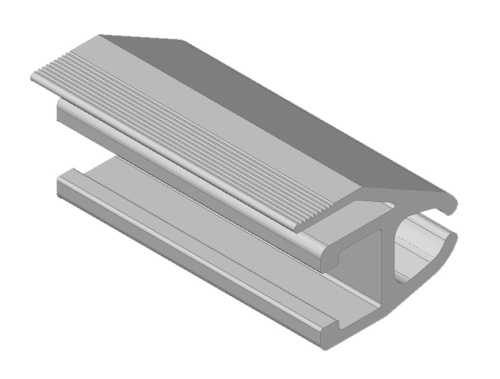

Track

Sometimes a curved edge is not desired. For a smooth seal or a straight fabric finish track is used. The track is fixed to a beam or a building and the fabric slides through the track. The track may be straight or bent. Tracks are extruded aluminium profiles.

Connection Points

Connection points connect the fabric membrane to structural elements. Structural elements include posts, overhead framework or walls. Connection points support and carry loads imposed by the membrane.

Connection points are determined by design and site limitations eg Alternating connection points on twisted hypar shade sails lead to interesting 3D effects.

Shade Hardware

Shackles, turnbuckles, terminal end swages, bow shackles, wire rope grips, are just a few of the hardware choices available for connection points in shade structures. Tensioned structures commonly consist of steel cabled hems with threaded end fittings. Hardware comes in 316 and 304 grade stainless steel and 8.8 structural and 4.6 regular grade galvanized steel.

Structural loads and requirements for a tensioned membrane structure dictate the size and shape of hardware.

A wide selection of shade sail fittings and hardware are available for general sale from our E-shop by following the link below.

Engineering

Engineering is recommended for all shade structures. Engineering will specify footings, steel sizes, cabling and loads to ensure structural integrity and compliance is achieved for the project in its location. After the project is constructed, final engineering certification confirms the structure was built to construction plans.

Abacus Shade Structures offers engineering as an additional level of professional reassurance in an area which may be technical and quite unfamiliar to clients.